Stocking

Distributor

of Cast Aluminum Pressure Blowers, High Pressure Blowers, Radial Tip

Fans,

FRP Fans, Propeller Fans, Vane Axial Fans, FRP Ventilators, OEM

Blowers,

Prop Fans, Fan Air Kits, Blower Wheels, Backward Curved Wheel

Blades,

Fan Wheels, Paddle Fan Wheels, OEM Fans, OEM Ventilators, New York

Blower

fans, NYB Blowers, Cincinnati Fans, Cincinnati Blowers, Aerovent Fans,

Twin

City Fan and Blower, Twin City Blowers, Robinson Fans,

INDUSTRIAL FANS INDUSTRIAL FANS |

|||||||||

|

|||||||||

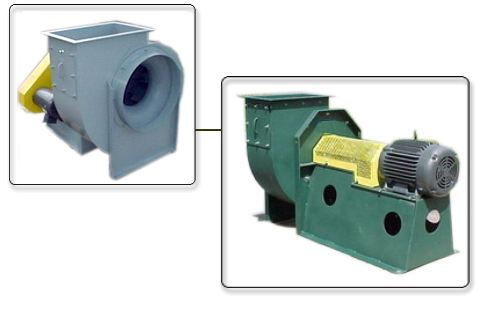

With pressures to 130" WG and volumes to 20,000 CFM, the range of the Canada Blower Pressure Blower has been widened to include a selection of more than 100 wheel / housing combinations. Six blower arrangements and eight discharge positions are available for most blower models. Although direct drive is specified for most applications, belt driven models are available as well.

Canada Blower pressure blowers are characterized by very stable performance: the pressure curve remains stable from wide-open to close-off, thus blower instability, or pulsation, is eliminated even when "turn-down" approaches zero flow. Standard Canada Blower alluminum dual-tapered wheel ensures optimum efficiency, an optional straight radial steel wheel is available for more rugged applications. NIS-CO advanced wheel and aerodynamic housing design combine for air-handling efficiency superior to conventional radial-wheel designs.

Production of air scrubber blowers, fume collector fans, positive displacement blowers, Aeroven Blowers, Twin City, NYB fans, blowers & fans repair and rebuild, Lau fans, plug fans ventilators, sheldons fans blowers, cooling fans, FRP ventilators, industrial mancoolers, Cincinnati fans / blowers, air polution control ventilators, blowers and fan exhaust systems, air make-up fans, air knife pressure blowers, high pressure blowoff fans, burner blowers, combustion process fans, conveyor blow-off fans, air canon fans, dust collector blowers, finishing systems fans, fan exhausters, fume exhaust ventilators, furnace fan blowers, incinerator fans.

Engineers of alloy pressure blowers, pressure blowers with high temperature construction, stainless steel, aluminum, and fabricated steel construction. Supply of replacement centrifugal fans, centrifugal blowers, and parts for centrifugal fans, and centrifugal blowers manufactured by Buffalo Blower in New York, Twin City Fan, Northern Blower, Chicago Blower, Sheldons, Cincinnati Fan, Hartzell, IAP, Industrial air products, Canadian Blower, Howden Buffalo, Penn Ventilation, Penn-Barry, Barry Blower, ACME, Aerovent, Alphair, American Fan, Lau Industries, Clarage, Delhi, Canarm, Leader Fan, Daltec, ABB, Flakt, Flaktwoods, Woods, MK Plastics, Robinson Industrial, Garden City Fan, Loren Cook, Jen-air, Jenn Fan, Aeroflo, Grainger, Greenheck, Kice Fan, ILG Industries, Canada Fan, Industrial Air, Ceilcote, Breidert, Anderson 2000, Solar & Palau, Strobic air, Trane, TCF Axial, Aerovent ventilating.com fanblower.com highpressureblower.net industrialblowerfan.com industrialfanblower.net industrialfanblower.com pressureblower.net northernindustrialsupplycompany.com industrialpressureblower.com tenderall.com chicagoblowercanada.com cbblower.com buffaloblower.com buffalofan.com nis-co.com canadianblower.com olegsystems.com canadablower.com abbblower.com acmefan.net industrialblower.net fansandblowers.net americanblower.net barryfan.com cincinnatifan.net canadafans.com barryfan.net pennbarry.net pennfan.net tcffan.com

Canada Blower AF / BC Custom Heavy-Duty Fans:

High pressure Airfoil AF Fans provide more high-efficiency choices based on selection criteria. These Canada Blower fans are ideally suited for a wide range of high-pressure, industrial-process ventilation applications including: combustion air, solvent recovery, thermal oxidation, fluidizing, combustion, and air recirculation.

Canada Blower HP AF fans are also available with single thickness airfoil ST wheel designs for slightly contaminated gas streams and alternate fan performance.

A determination must be made as to whether or not the system discharge duct configuration will allow the use of an energy-saving evase. Depending upon the specific fan size and point of operation, an evase can significantly increase fan efficiency.

Fans handling hot airstreams must be kept in operation after system shutdown, until the airstream cools below 200 F to prevent damage to the fan. The fan wheel or shaft might otherwise distort due to “heat-soaking”. The shaft cooler on heat fans is only effective while rotating.